Wear & Tear

An air suspension system is made up of multiple components that work in tandem to offer the best ride possible. The main component, air springs and air struts, are built with rubber air sleeves.

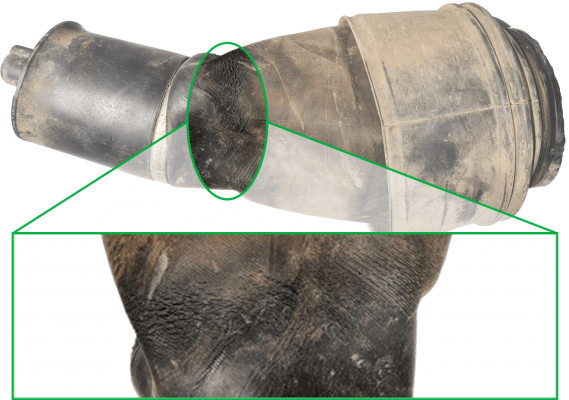

Since rubber is a natural product, it can wear out simply due to normal wear and tear. Over time, rubber can dry rot and small cracks can form where the sleeve rolls and bends along the rolling piston. These cracks allow air to leak out of the air suspension system causing it to run inefficiently and increasing safety concerns.

External conditions such as climate, road conditions, and abrasion from constant dirt and road debris can affect an air suspension component’s functionality and lifespan. For example, colder temperatures stiffen the rubber while hotter temperatures will dry it out faster. Both conditions can act as a catalyst to burst an already worn air sleeve.

Quality Makes a Difference

Top-tier components including rubber, crimping rings, O-rings, and piston material make up the overall composition of an air spring.

While some inexpensive air springs may look identical to the original part, there are major differences. Inferior rubber, lower grade components, and consolidated piston design can result in lower burst pressure, fitment difficulty, reduced damping comfort, and increased noise, vibration, and driving harshness.

Arnott’s goal is to engineer and build long-lasting products. We use the highest quality parts, including Continental ContiTech rubber sleeves and Tier 1 components for our air springs and struts.

Replacing Parts

Examine air sleeves during your vehicle’s inspection. Replace them to avoid larger or new cracks from developing. Typically, a high-quality air spring should be replaced every six to ten years.

When an air spring or strut has reached the end of its lifespan, replacing in pairs is highly recommended. Suspension components on both sides of the vehicle have likely experienced the same external conditions. Therefore, the components will have had similar wear and tear. It is highly probable that the functioning air spring or strut will soon have comparable issues if not replaced at the same time as the one that failed.

Damping efficiency is another reason to replace in pairs. If only one side of the axle has a new air spring or strut installed, there will be a substantial difference in the vehicle’s damping efficiency. It will impair the ride, handling, and stability, leading to unpredictable, possibly dangerous, driving behavior and situations.

Although it is not mandatory, Arnott highly recommends replacing air springs or struts in pairs. Doing so will ensure a safe, comfortable ride as well as prevent another trip to the mechanic.